In today’s highly interconnected economy, supply chain resilience is no longer just a defensive strategy…

Introduction: The Critical Need for Supply Chain Resilience

In today’s highly interconnected economy, supply chain resilience is no longer just a defensive strategy; it’s essential for survival and competitiveness. With ongoing disruptions—from pandemics to geopolitical upheavals, the ability to withstand and recover from disruption to the supply chain is paramount.

Why This Matters: Moving Beyond Traditional Risk Management

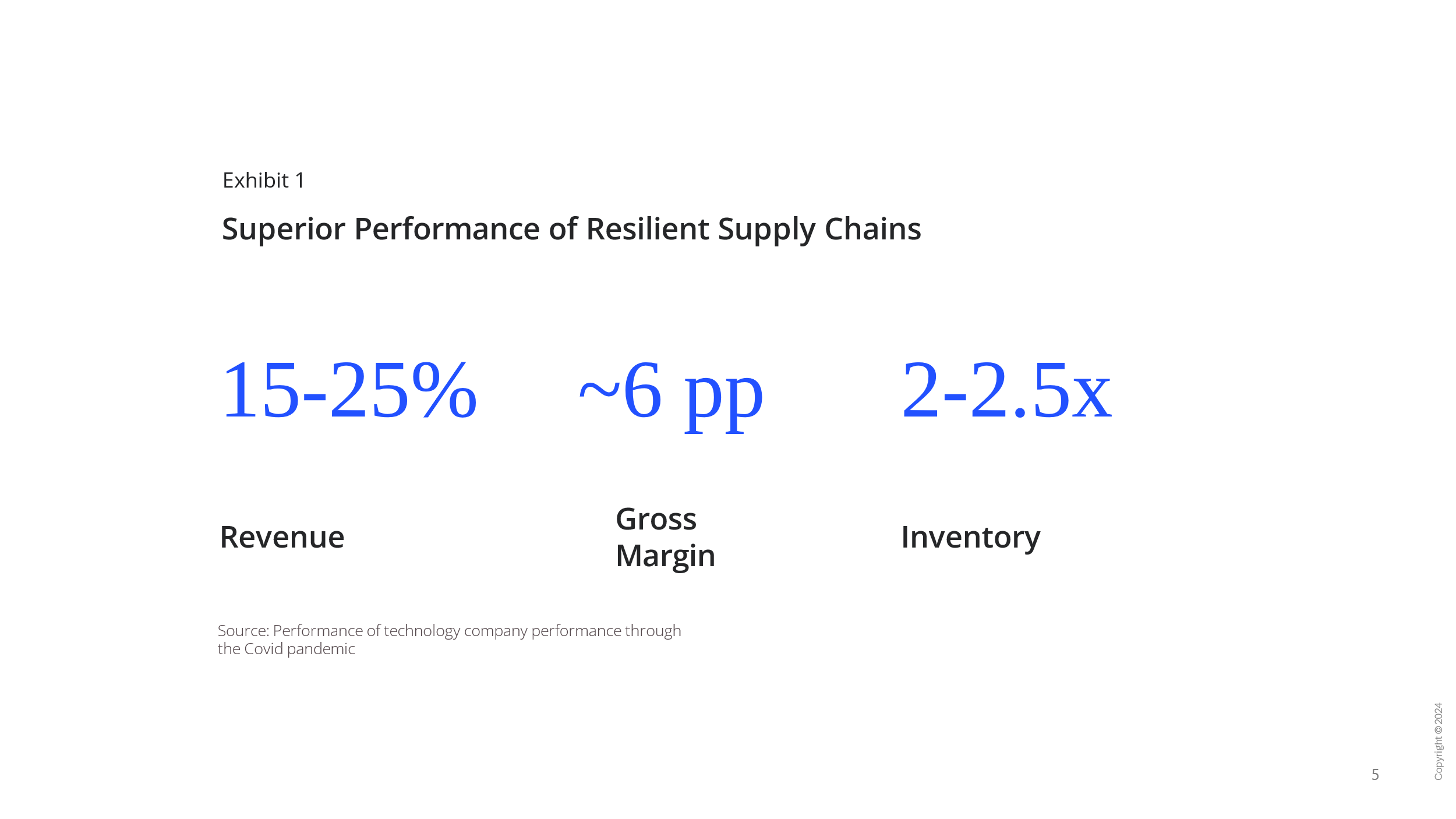

Traditional risk management focuses on identifying and mitigating known threats, but resilience is about broader preparation and adaptability. Supply chains must be equipped to respond to disruptions that cannot always be predicted. Data from recent global disruptions shows that companies with high resilience achieved 15–25% higher revenue growth and improved gross margins by ~6 percentage points, significantly outperforming less-prepared competitors. For CXOs, this means recognizing resilience as an integral component of supply chain strategy, not just a contingency.

Understanding the Core Dimensions of Resilience‘

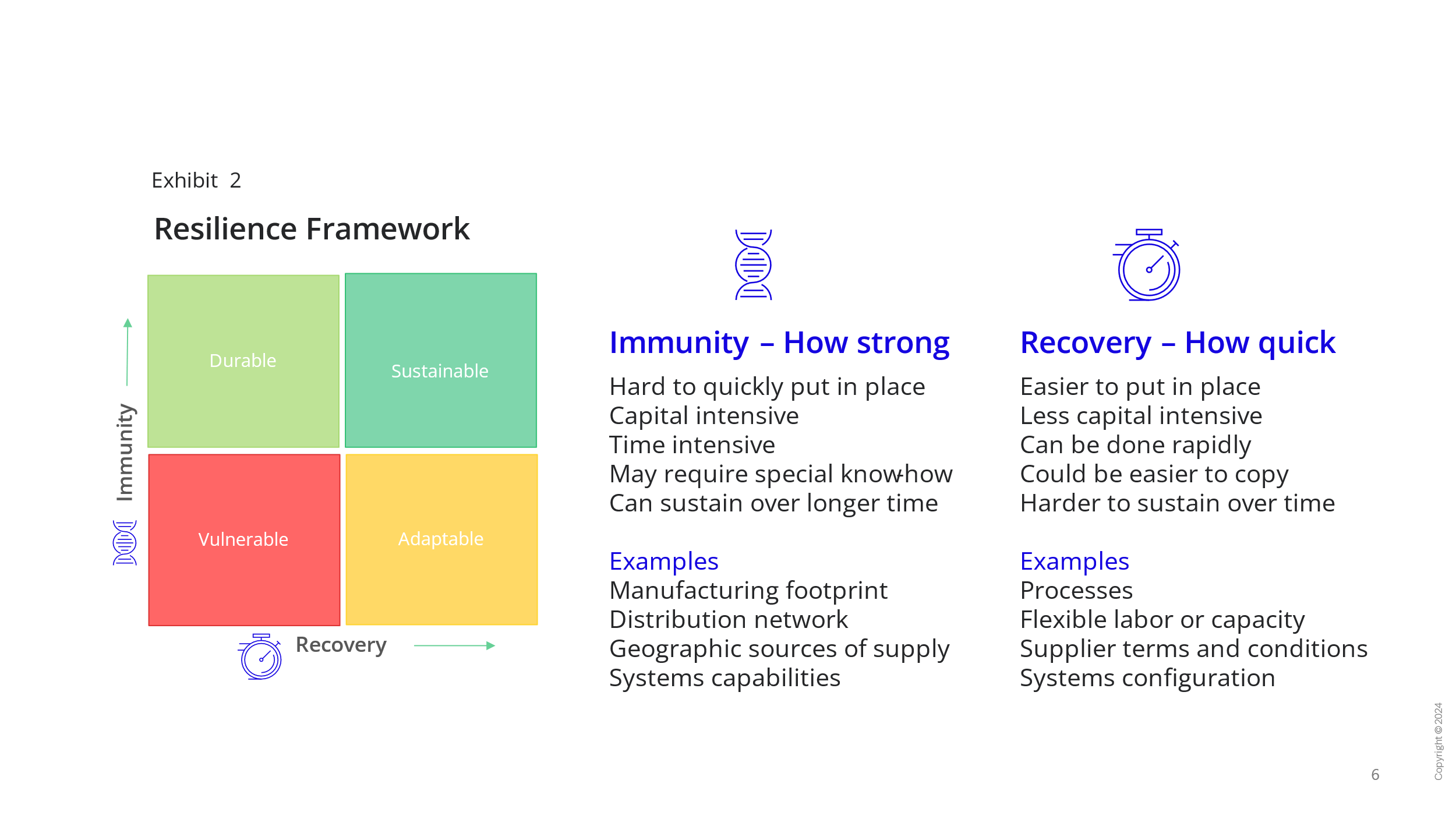

To achieve true resilience, supply chains must incorporate two critical dimensions:

1. Immunity: Structural resilience, or immunity, focuses on strengthening supply chains against disruption through durable assets. Examples include building a geographically distributed manufacturing footprint and securing diversified sources of supply. Immunity requires upfront investment and careful planning but establishes a stable foundation.

2. Recovery: Adaptive resilience, or recovery, enables companies to respond quickly and reconfigure supply chains as disruptions occur. Elements like flexible labor arrangements, agile supplier contracts, and adaptable processes fall under this category. Recovery capabilities can be implemented rapidly but require continuous updating and organizational alignment.

By balancing immunity and recovery, organizations can build a supply chain that is resilient – robust and adaptable.

Zoom Out: Key Capabilities for End-to-End Resilience

A resilient supply chain strengthens capabilities across the entire supply chain, from product development to delivery and service. Here are examples of capabilities that build varying levels of resilience across the supply chain.

Product Development: Emphasize modular design and component flexibility, enabling rapid modifications to products in response to changing demands.

Planning: Strengthen forecasting process and develop flexible planning systems and data models.

Sourcing: Diversify supplier network and establish multi-sourcing options.

Manufacturing and Logistics: Adopt flexible manufacturing models and diversify location footprint

Logistics: establish alternative transportation modes and warehousing locations to ensure delivery continuity.

To measure resilience, it’s necessary to quantify the capabilities—by scoring the maturity of the capability and weighting its contribution to resilience. This helps organizations identify gaps to targeted levels of immunity and prioritize capabilities for improvement. This structured and quantitative assessment becomes the foundation for a targeted resilience roadmap.

Zoom In

A Framework for Assessing and Building Resilience

To build resilience, companies need a comprehensive framework for evaluating and enhancing supply chain capabilities. Effective resilience-building strategies involve:

1. Quantitative Assessments: Evaluate each supply chain capability for maturity and contribution to resilience. For example, companies should assess supplier diversity, manufacturing scalability, and inventory flexibility, assigning maturity scores and contribution weights.

2. Bridge gaps: Based on the assessment above, identify specific action to improve resilience, and develop an implementation roadmap.

3. Organizational Commitment and Roadmap Development: Effective resilience-building requires commitment from senior management, with a funded, actionable roadmap. Prioritize high-impact capabilities and establish clear KPIs to measure progress.

4. Continuous Monitoring and Adaptation: Since resilience is a dynamic capability, companies must monitor both internal and external factors, including geopolitical shifts, economic indicators, and supplier ecosystem health. Ongoing monitoring creates an early-warning system that helps leaders adapt proactively to emerging risks.

Leveraging Generative AI for Supply Chain Resilience

GenAI can play an important role in resilience, providing supply chain leaders with real-time analysis and scenario modeling capabilities. GenAI applications can help companies:

Analyze Scenarios and Plan Proactively: By feeding GenAI models with relevant supply chain data and context, companies can explore various disruption scenarios and potential responses.

Develop and Refine Resilience Roadmaps: GenAI can help organizations refine resilience strategies, identifying gaps and suggesting tactical adjustments.

Enable Real-Time Problem Solving: GenAI’s rapid analysis capability allows for quick response strategies during disruptions, integrating human expertise with data-driven recommendations.

When implemented effectively into the immunity-recovery framework, GenAI models can become a powerful tool that augments human decision-making, helping companies stay agile and resilient.

Conclusion and Call to Action: Resilience as a Strategic Imperative

In a world marked by constant disruption, supply chain resilience is no longer optional. Leaders must make resilience a strategic priority by adopting a robust quantitative framework, building end-to-end capabilities, and integrating continuous monitoring with AI-driven insights.

Next Steps for Leaders

Begin with an end-to-end resilience assessment across your supply chain, scoring capabilities in every domain from sourcing to delivery. Define a resilience roadmap with prioritized initiatives and key performance metrics. By investing in resilience, your organization will be prepared to navigate unanticipated but guaranteed disruptions, secure a competitive edge, and achieve sustainable growth. CI

By Srini Bangalore, Founder and Chief Client Officer

What the Paul Weiss Case Reminds CEOs and Boards About Stakeholder Alignment

By Srini Bangalore, Founder & Chief Client Officer

The U.S. Congress’s mandate that ByteDance divest TikTok or face a ban is a significant development in global tech regulation.

The $24.6 billion Kroger-Albertsons merger, announced in 2022, aimed to create a grocery powerhouse to compete with Walmart and Amazon. However, regulatory opposition and public backlash…

Mergers and acquisitions are among the most transformative moves a company can make to accelerate growth — but it is commonly known that 70% or more of M&A transactions fail …

Between the forces of genAI disrupting all industries and a change of administration in the US, there is a widespread belief that M&A activity will pick up.

By Srini Bangalore and Cate (genAlyst™)

By Srini Bangalore, Founder & Chief Client Officer | Cate, genAlyst

CASETEAM Launches as GenAI-native and Hybrid-first Management Consulting Firm, Innovating a New Model that Makes Top-tier Problem-solving Accessible to More Organizations

By Integrating GenAI with Human Ingenuity, CASETEAM Creates a New Model for Management Consulting

Q&A with Cate, genAlyst at CASETEAM

[Note: Cate is a genAI model configured for the needs of CaseTeam]

Share this Post